|

|

| Brand Name: | KTS |

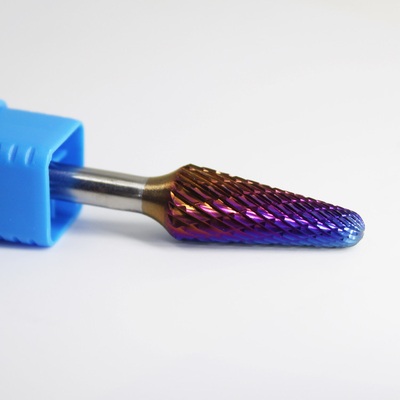

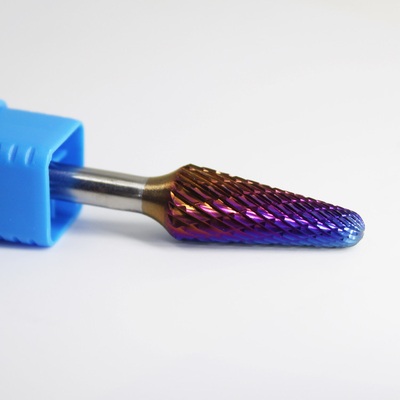

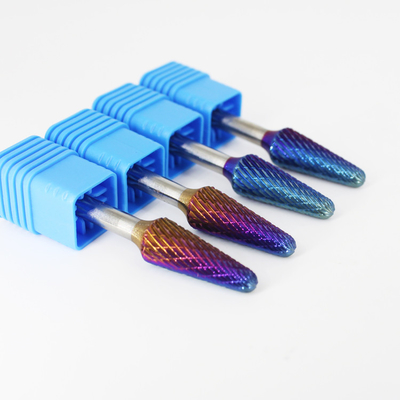

| Model Number: | Type-L |

| MOQ: | 100PCS |

| Price: | USD1.1-6 PER PCS |

| Payment Terms: | Western Union, T/T, Western Union, MoneyGram |

| Supply Ability: | 20000 PCS PER MONTH |

![]()

Double cut, Single cut, Diamond cut, Coarse cut, Fine cut, Non-ferrous cut.

| Manufacturing Process | Hardness | Model | Raw Material | Applications |

|---|---|---|---|---|

| Grinding, Polishing, and Deburring | High Hardness (60HRC) | Cylindrical | Tungsten Carbide | Metal, wood, plastic, composite materials, etc. for grinding, polishing, and deburring |

| Precise manufacturing using advanced grinding techniques | 60-65 HRC | Various | Solid Tungsten Carbide | Automotive, aerospace, mold making, metal fabrication, woodworking, and more |

| Unique tooth geometry for smooth and efficient material removal | - | Standard and Customized | Premium-grade Tungsten Carbide | Deburring, shaping, chamfering, and finishing of various materials |

| Precision ground flutes for improved chip evacuation and reduced heat buildup | - | Multiple Options | High-density Tungsten Carbide | Ideal for use on ferrous and non-ferrous metals, alloys, plastics, and wood |

This tool can fit with pheumatic tool or power tool, and they are good at gring, polishing and deburring.

Cylindrical tungsten carbide burrs are versatile tools used in a variety of applications including grinding, polishing and deburring. It has a cylindrical shape and is designed to remove material and create precise cuts and contours in a variety of materials.

The files are made of tungsten carbide, a highly durable and wear-resistant material known for its exceptional hardness and heat resistance. This ensures that the burrs retain their sharpness and longevity even when used in demanding applications.

In terms of grinding, the cylindrical shape enables efficient material removal and surface shaping. It can be used to smooth rough edges, deburr metal parts or create intricate patterns and details.

For polishing, the burr's abrasive surface makes it effective at removing scratches, burrs, and other imperfections, leaving a smooth, polished surface. It can be used on a variety of materials such as metal, wood, plastic and composites.

In addition, deburring effectively removes burrs and sharp edges, improving the overall safety and functionality of the workpiece.

Custom service:

Logo can be laser marked on burr shank, and custom sticker on box.

Wear Personal Protective Equipment: When using tungsten rotary burrs, it is essential to wear appropriate personal protective equipment, including safety glasses, gloves, and a protective mask, to prevent potential injuries.

Select the Proper Burr: Choose the appropriate type, shape, and size of tungsten rotary burr based on the specific machining task and the material being worked on.

Control Speed: Adjust the speed of the rotary tool according to the hardness of the work material and the diameter of the burr. Follow the manufacturer's recommendations for optimal speeds.

Secure Workpiece: Ensure the workpiece is securely clamped during machining to prevent vibration and movement, ensuring accuracy and safety during processing.

Avoid Excessive Pressure: Avoid applying excessive cutting pressure to prevent premature wear of the rotary burr and to enhance machining efficiency.

Regularly Inspect the Burr: Periodically check the wear condition of the tungsten rotary burr during use. Replace the burr when significant wear is observed.

Maintain Cleanliness: After use, clean the tungsten rotary burr, remove cutting debris, and store it in a dry, clean environment to prevent rusting.

Follow Manufacturer's Recommendations: Adhere to the manufacturer's guidelines for the proper use and maintenance of tungsten rotary burrs to ensure safety and optimal performance.

Within 5 pcs of samples are for free to test quality.

Pack carbide burr with plastic tube, with blue, green, yellow cap, or five connected bpx; 8pcs aluminium set, 8pcs plastic set.

![]()